Modes of shear

Shear forces in chromatography media are a byproduct of the modes of flow through a particular device. Since different architectures produce different flow modes, different architectures mediate different modes and intensities of shear stress. Managing shear stress is an important part of process development, especially for large biomolecules like DNA plasmids and supramolecular assemblages like virus particles and extra-cellular vesicles.

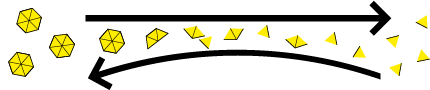

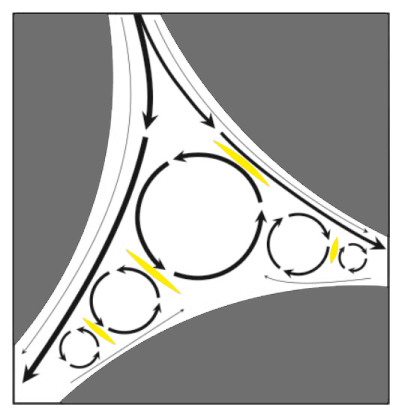

There are two primary modes of shear in hydrodynamic systems. First, shear stress is produced when an object is subjected to anti-parallel forces. Tearing a sheet of paper is an example. In chromatography, this mode is associated with turbulent flow and is sometimes referred to as turbulent shear. The second mode is laminar shear (Image 1). It results when an object is subjected to parallel flow strata moving at dramatically different velocities. An extreme example would be a projectile passing through an object moving more slowly in the same direction (Image 2). Turbulent shear forces are the greater concern for biomolecule stability because they impose the greatest stress.

Grinding effect as a consequence of turbulent shear stress.

Laminar shear stress is relatively limited because the solutes move in the same direction as the surrounding liquid:

- shear stress in monoliths is almost exclusively laminar,

- shear stress in porous particle columns is dominantly turbulent.

Eddy circulation follows the direction of the dominant bulk flow current. This creates areas where eddy flow is antiparallel with secondary bulk flow currents and adjacent eddies. Shear zones, marked red on Image 3, occur at the interfaces between counter-current flows. Unlike dispersion, which is independent of flow rate, turbulent shear stress is directly proportional to flow rate. This is because it increases the grinding intensity at counter-current interfaces.

Shear stress from surface microturbulence is negligible in all media types because flow rate approaches zero at surfaces due to friction.

Several factors can affect shear potential independently from the mode of flow:

- Solute shear strength. Shear forces are known to strip lipid envelopes from some viruses, to break brittle capsids of nonlipid-enveloped viruses, and to nick large DNA capsids.

- Solute size. The larger a solute is, the more likely it is to simultaneously occupy flow strata moving in different directions and/or at different rates.

- Viscosity. Viscosity is directly proportional to shear stress because it increases friction.

Continue to "Capacity as a function of structure and transport".