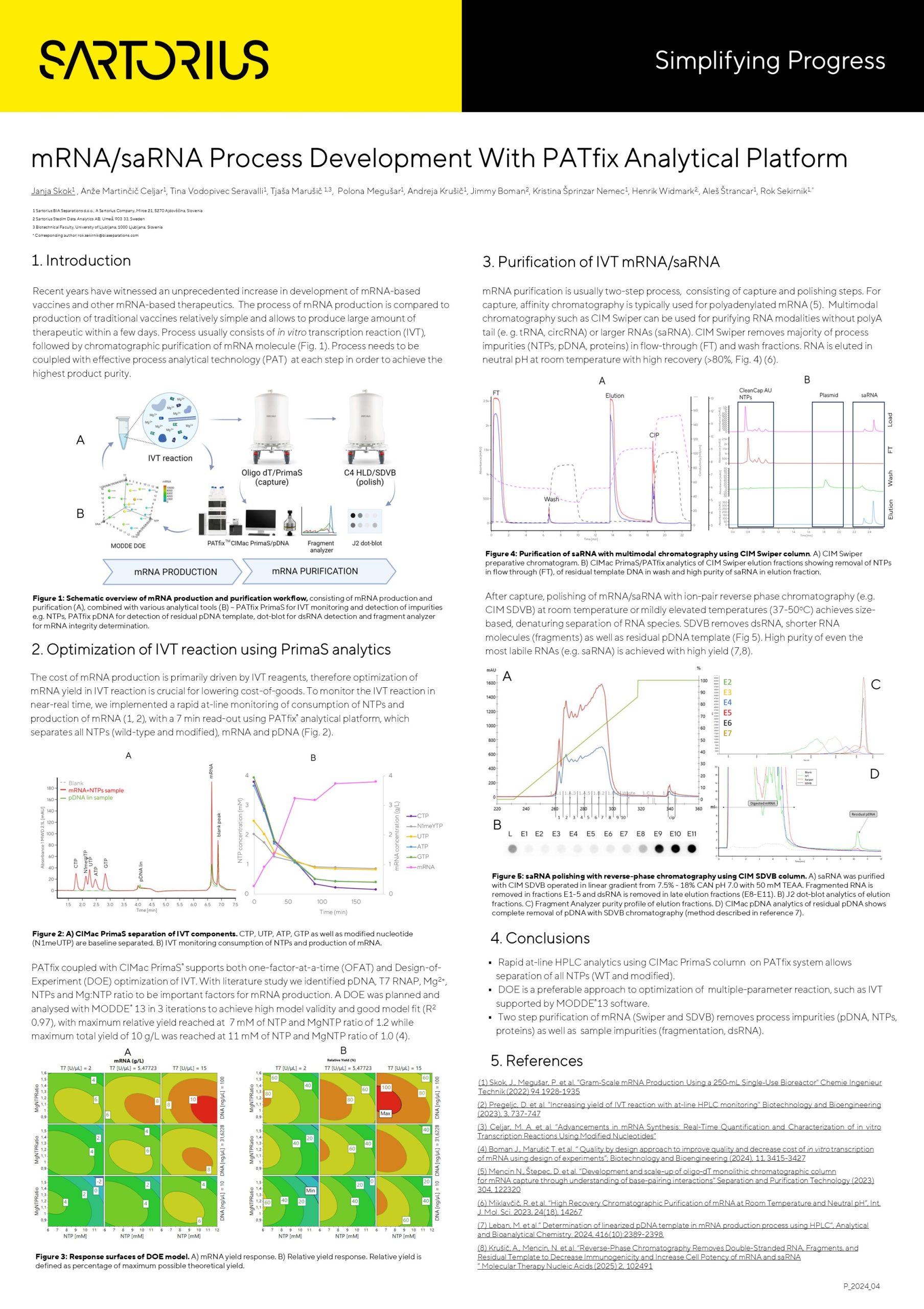

Recent advancements in mRNA-based vaccines and therapeutics have simplified production compared to traditional vaccines, enabling rapid large-scale output. The process involves in vitro transcription (IVT) and chromatographic purification, requiring effective process analytical technology (PAT) for optimal purity.

Cost is driven by IVT reagents, making yield optimization crucial. Rapid at-line monitoring using the PATfix® platform allows near real-time tracking of NTP consumption and mRNA production. A Design of Experiment (DOE) approach, supported by MODDE® 13 software, identified key factors for mRNA production, achieving high model validity and yield optimization. mRNA purification involves two steps: capture using affinity chromatography for polyadenylated mRNA, and polishing with ion pair reverse phase chromatography for high purity. The CIMac PrimaS® column on the PATfix system enables efficient separation of NTPs and RNA species, ensuring high recovery and purity.