In the field of gene therapy, adeno-associated virus (AAV) manufacturing plays a pivotal role in delivering effective treatments. As the demand for high-quality AAV products increases, manufacturers face the dual challenge of ensuring both purity and efficiency in their processes.

This blog post explores the critical aspects of AAV purification and analytics, highlighting the scientific approaches that address these challenges and enhance overall product quality. By understanding and overcoming these hurdles, researchers and manufacturers can optimize their workflows and contribute to the advancement of gene therapy solutions.

Overcoming Challenges in AAV Purification

In the dynamic landscape of AAV manufacturing, achieving consistent product quality is crucial. This requires well-defined and robust processing steps, particularly in the purification phase. A key challenge in AAV production is optimizing the purification process to ensure high purity and yield, which are essential for the success of AAV therapies. The process must also be scalable and easily implemented in a GMP environment. Success often depends on a thorough evaluation of critical consumables, such as filters and columns, to establish robust process parameters. With numerous variables influencing success, a tight integration between purification and analytics during process development is vital. Rapid feedback on full capsid recoveries and impurity removals during the optimization of downstream steps leads to improved product outcomes.

Capture Step Challenges and Solutions:

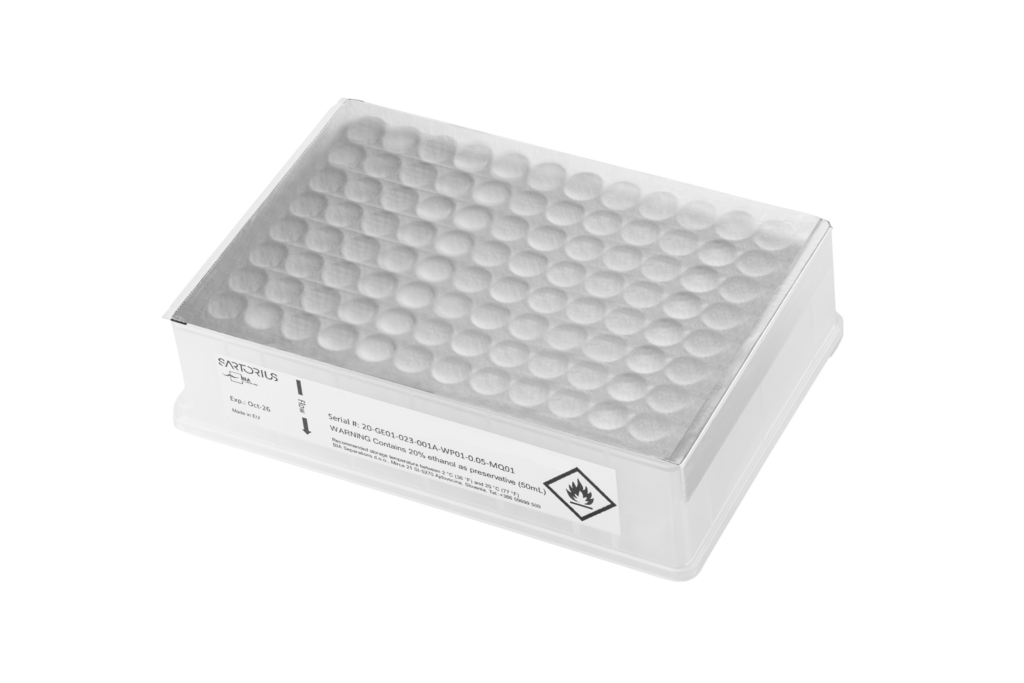

Different AAV types and their chimeras necessitate a versatile platform solution. In the first chromatography step, the focus is on removing process-related impurities, such as whole cell DNA and proteins. A cost-effective and versatile solution for this step is a monolithic column, strong Cation Exchanger (CEX), which allows binding and elution of any AAV serotype and engineered capsids. This multi-use column can be cleaned with sodium hydroxide, reducing the cost per process.

Polishing Step Challenges and Solutions:

Separating empty and full capsids (E/F) is challenging and serotype-dependent, requiring high dilutions or buffer exchange between the capture and polishing steps. However, with advanced, high-reproducibility monolith technology, it is possible to achieve reproducible empty and full separation across the entire scale. This technology allows for robust implementation of step gradients and advanced chromatographic techniques, such as flow-through mode, which preferentially enriches full AAV capsids while allowing empty capsids to pass through.

Overcoming Challenges in AAV Analytics

The analytical aspect of AAV manufacturing is equally critical, as it supports the characterization of different AAV serotypes from various in-process samples, by providing empty-to-full capsid ratio.

However, several challenges persist:

- Low Resolution: Traditional chromatographic methods often lack sufficient resolution, making it difficult to distinguish between empty and full capsids. Monolithic analytical columns leverage monolith technology to achieve high resolution between similar and large analytes, such as empty and full AAV capsids.

- Low Purity and Incomplete Separation: Conventional methods typically achieve only about 70% purity of full capsids. Our novel approach to analytical chromatography allows for baseline separation of different AAV subpopulations, enabling simultaneous analysis with multiple detectors. This facilitates the calculation of process recoveries and monitoring of undesirable subpopulations.

- Complex Sample Analysis: Estimating the full percentage in upstream complex samples usually requires a combination of analytical methods. Our orthogonal multi-detector analysis overcomes challenges posed by interfering impurities, providing a comprehensive solution for analyzing process samples.

By integrating these advanced solutions, we provide a complete platform that includes not only the hardware but also the methods, buffers, columns, and standards required for successful AAV analytics. This comprehensive approach accelerates process development and enhances the purification of full AAV capsids from complex upstream material.

Streamlining AAV Purification with Expert Support

Developing an effective AAV purification process can be challenging, but support is available. A dedicated process development team can assist in tailoring a purification process to specific AAV samples. Once optimized, comprehensive SOPs and seamless tech transfer are provided, supported by on-site experts. For more detailed insights, watch the video to learn how monolithic chromatography columns, analytical support, and additional services can enhance your AAV manufacturing journey.